🦋 Understanding AWWA Butterfly Valves: Standards and Performance

Learn how AWWA butterfly valves perform in water systems. Discover standards, uses, and why resilientgatevalve is your trusted valve manufacturer

In the world of water infrastructure and flow control, AWWA butterfly valves are considered one of the most reliable and efficient types of valves. These valves are specially designed to meet the strict standards of the American Water Works Association (AWWA) ensuring they deliver long-term durability, excellent sealing, and smooth operation in water systems of all scales.

Whether you are managing a municipal water supply, an irrigation network, or an industrial treatment plant, choosing the right valve can make a big difference. In this blog, we will break down everything you need to know about AWWA butterfly valves from their design standards to their performance benefits and how they compare with other valves such as resilient seated sluice valves, air valves, and non-return valves.

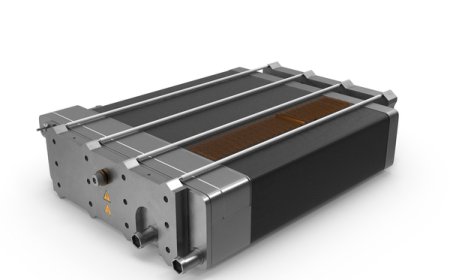

? What is an AWWA Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a circular disc to control the flow of water. When the disc is turned parallel to the pipe, water flows freely. When the disc is turned perpendicular, it stops the flow.

An AWWA-certified butterfly valve is built to meet the standards defined by AWWA primarily AWWA C504 and AWWA C516. These standards focus on factors like materials, pressure ratings, torque, coating, durability, and testing procedures.

These valves are particularly important for large-diameter pipelines found in municipal water systems, wastewater plants, irrigation projects, and even industrial process water lines.

? AWWA Standards: C504 and C516 Explained

? AWWA C504:

This standard applies to rubber-seated butterfly valves typically used in water transmission and distribution systems. It covers valves from 3 inches to 144 inches in diameter and defines:

-

Body and disc materials (cast iron, ductile iron)

-

Pressure classes (up to 250 psi)

-

Shaft designs

-

Seat and sealing requirements

-

Testing and quality checks

? AWWA C516:

This is a newer standard focused on low-torque, rubber-seated butterfly valves with improved energy efficiency. It includes updates for reduced torque design, improved coatings, and corrosion resistance.

By following these standards, manufacturers ensure their valves are safe, reliable, and long-lasting.

? Performance Advantages of AWWA Butterfly Valves

Lets take a look at the core benefits that AWWA butterfly valves offer:

1. Durability and Long Service Life

These valves are designed for decades of reliable operation, even under demanding flow conditions. With corrosion-resistant coatings and robust construction, they can handle harsh water environments with ease.

2. Bubble-Tight Sealing

Thanks to their resilient rubber seats, AWWA butterfly valves offer a leak-free shut-off, which is essential for potable water systems, fire protection lines, and pressurized mains.

3. Low Torque, Easy Operation

They require less torque to operate, which reduces the size of gear operators or actuators saving energy and reducing automation costs.

4. Cost-Effective for Large Pipes

Compared to gate or globe valves, butterfly valves are more compact and affordable, especially in pipes larger than 400 mm.

? How Do They Compare with Other Valve Types?

?? Resilient Seated Sluice Valves

As a trusted resilient seated sluice valve manufacturer, resilientgatevalve provides robust options for on/off flow control in pipelines. Sluice valves provide excellent shut-off and are great for low-pressure systems. However, they are bulkier and slower to operate compared to butterfly valves, especially in large sizes.

?? Metal Seated Sluice Valve

Metal-seated valves are preferred for high-temperature or abrasive fluid environments. They are strong and wear-resistant but not as efficient for quick flow control or low-torque operation like butterfly valves.

?? Air Valves Single and Double

Air valves (both single and double type) are critical in preventing air accumulation and ensuring smooth pipeline operation. While they don't control flow directly, they are often used alongside AWWA butterfly valves to protect the system during filling and draining.

?? Non Return Valve (NRV)

A non-return valve or check valve allows water to flow in only one direction, preventing backflow. These are essential for protecting pumps and avoiding contamination. However, NRVs dont provide control over flow rate thats where butterfly valves come in.

?? Pressure Reducing Valve (PRV)

A pressure reducing valve ensures the outlet pressure stays within safe limits, especially when dealing with high-pressure mains. In many systems, PRVs and butterfly valveszz are used together the butterfly valve isolates the flow, while the PRV manages the pressure.

? Applications of AWWA Butterfly Valves

These valves are used in a wide range of applications, including:

-

Urban water supply and distribution systems

-

Pumping stations and water treatment plants

-

Industrial cooling and process water systems

-

Agricultural irrigation canals

-

Fire protection systems

-

Wastewater management networks

In each of these systems, AWWA butterfly valves offer fast operation, tight shut-off, and low-maintenance performance.

? Installation and Maintenance Tips

To get the best performance from AWWA butterfly valves:

-

Always follow torque specs for flange bolts

-

Ensure clean pipeline before installation

-

Choose the right actuator type (manual, electric, or pneumatic)

-

Conduct regular visual checks for leaks or corrosion

-

Grease moving parts and seals as needed

Thanks to their simple design, butterfly valves are easier to maintain compared to multi-part valves like sluice or globe valves.

? Why Buy from resilientgatevalve?

At resilientgatevalve, we provide complete valve solutions for municipal and industrial water systems. Our product range includes:

-

AWWA Certified Butterfly Valves

-

Resilient Seated Sluice Valves

-

Metal Seated Sluice Valves

-

Air Valves (Single and Double)

-

Non Return Valves (NRV)

-

Pressure Reducing Valves (PRV)

All our products are engineered with a focus on durability, performance, and compliance with AWWA, BIS, and international standards. Whether youre upgrading an existing network or building a new one, resilientgatevalve is your trusted partner for flow control.

? Conclusion

AWWA butterfly valves are a reliable, affordable, and efficient solution for water control across a wide variety of applications. Their standardized design, excellent performance, and low maintenance requirements make them a preferred choice among engineers and project managers alike.

When you pair these valves with additional components like air valves, sluice valves, and non-return valves, you create a water system that is safe, durable, and future-ready.

For high-quality valves that meet AWWA standards and offer long-term peace of mind, choose resilientgatevalve.