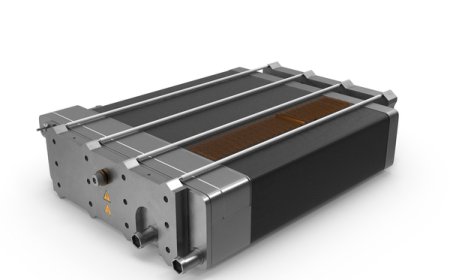

Manifold Casting-Its Types, Materials, Advantages, and Industrial Applications

Learn about manifold casting, including its types, materials, advantages, and industrial applications. Discover how manifold castings are used in various industries for optimal performance and reliability.

A manifold serves as a common intersection point where multiple inputs and outputs connect and collect or distribute gases or liquids competently. In other industrial applications, manifold casting is known as the creation of a manifold - a component responsible for directing the flow of a liquid or a gas. Manifolds are used in many applications, for example, in hydraulics, engines, etc., where they control the flow and distribution of fluids or gases.

Types of Manifold Castings

Manifolds of different designs can be employed according to the application and the liquid control systems. The following are some of the most popular:

1. Pneumatic

Manifold is intended predominantly for air or gas. It couples multiple pneumatic valves and an actuator for fail-safe, smooth air dispensing. And there are applications in automation, robotics, and the food industry.

2. Hydraulic

These manifold casting are used in hydraulic systems to control the flow of fluid between pumps, actuators, and other devices. They are used in construction machinery, aerospace, and manufacturing.

3. Intake

This is the manifold that connects to the engine and introduces the air/fuel mixture to the cylinders. It provides for better engine performance and better fuel economy. It is compatible with car, truck, racing, and aviation engines.

4. Exhaust

It is a base component of the internal combustion engine. It is a collection of gases emitted from the various cylinders, directed into one pipe. So it makes the engine more efficient and lowers the emission output. It is widely used in automotive, marine, and motorcycle applications.

5. HVAC

These manifolds help regulate temperature fluctuations in HVAC systems. They are believed to maximize power efficiency and working reliability. Common applications include residential and commercial facilities, refrigeration units, as well as various industrial cooling systems.

6. Fuel

This is a fuel injection system manifold for supplying fuel to the cylinders of an engine. This is mostly applied in racing automotive, power generation for industry, and fuel systems of aircraft.

7. Valve

This manifold is advantageous in process industries where precise flow is required. It comprises a remainder of valves in a solid structure and thereby eliminates the need for complicated installation of pipes. It is typically found in oil and gas refineries, water treatment plants, and chemical processing.

What Are Some Basic Manifold Casting Materials?

Manifold may be made from any one of several materials. The material type of the manifold can influence the liquid compatibility and performance. For example, a manifold made of a material such as aluminum can exhibit a high resistance to a particular oil. When it comes to selecting a manifold material, it depends on the type of chemical or liquid being processed through the system, where it will be used.

What kind of industries use cast manifolds?

Cast manifolds are used for a variety of commercial uses because they can efficiently distribute liquids or gases and control their flow. Its major uses are:

1. In Hydraulic Systems

These systems are used to operate the movement of hydraulic fluids in various industrial applications, including construction, material handling, and farm implements. Besides, they ensure precise pressure control and flow rate regulation as well.

2. In the Automotive Industry

In automobiles, cast manifolds for exhaust and intake play an important role in the power management of the engine by controlling air or fuel into the cylinders and removing exhaust fumes. A correctly designed and running manifold improves fuel economy and reduces emissions. Cast manifolds in automotive applications are manufactured from, for example, materials such as aluminum and grey cast iron, which have benefits in respect of heat and corrosion resistance.

3. In the Oil and Gas Industry

Manifolds are also critical in the oil and gas sector, such as for well testing and production. Theyre able to divert liquids to storage or measurement systems that can also ease pressure and monitor flow rates.

Advantages Of Manifold Casting

Manifold casting offers a number of advantages:

1. It is Cost Effective

A. Manifold casting produces parts on a large scale. It is therefore cheap to make things like cars.

B. It can eliminate the need for extensive post-processing steps, such as machining, requiring even lower manufacturing costs.

C. Casting material can be reused, reducing the volume of the waste and the cost accordingly.

2. Allows for Design Flexibility

A. Casting enables the creation of complex geometries and internal molds that are difficult to achieve with competing techniques.

B. Designers may strategically place material only where it is needed. Thus, enhancing strength and functionality.

C. It is particularly useful for exhaust manifolds where complex geometries are necessary to enhance engine power output through improved exhaust flow.

3. Have Different Material Properties and Higher Performance

A. Various metals and alloys can be cast. Thus, provides a range of options for material selection based on different performance requirements.

B. Casting parts can be built strong and durable, perfect for tough uses such as engine manifolds.

C. Cast iron manifolds also retain heat, which may be beneficial for some engines. Steel manifolds, stainless in particular, do allow for good heat dissipation, and on high-performance industrial applications, this is advantageous.

D. Manifold casting can be made from stainless steel and aluminum for excellent corrosion resistance.

Final Words

Manifold casting is required in many industrial sectors. In industrial applications, it makes the distribution of gases and fluids easier, which improves the performance and increases system efficiency. As a top manufacturer of iron castings in the USA, AKP Ferrocast can improve production processes with high performance casting solutions.